Description

We have been digitalizing the processes of the world's largest corporations for years, through technologies deriving from Artificial Intelligence.We can boast extensive experience in the field of international projects at the corporate level. This know-how and the multiplicity of installations ensure rapid implementation, reliability and stability of the various solutions.

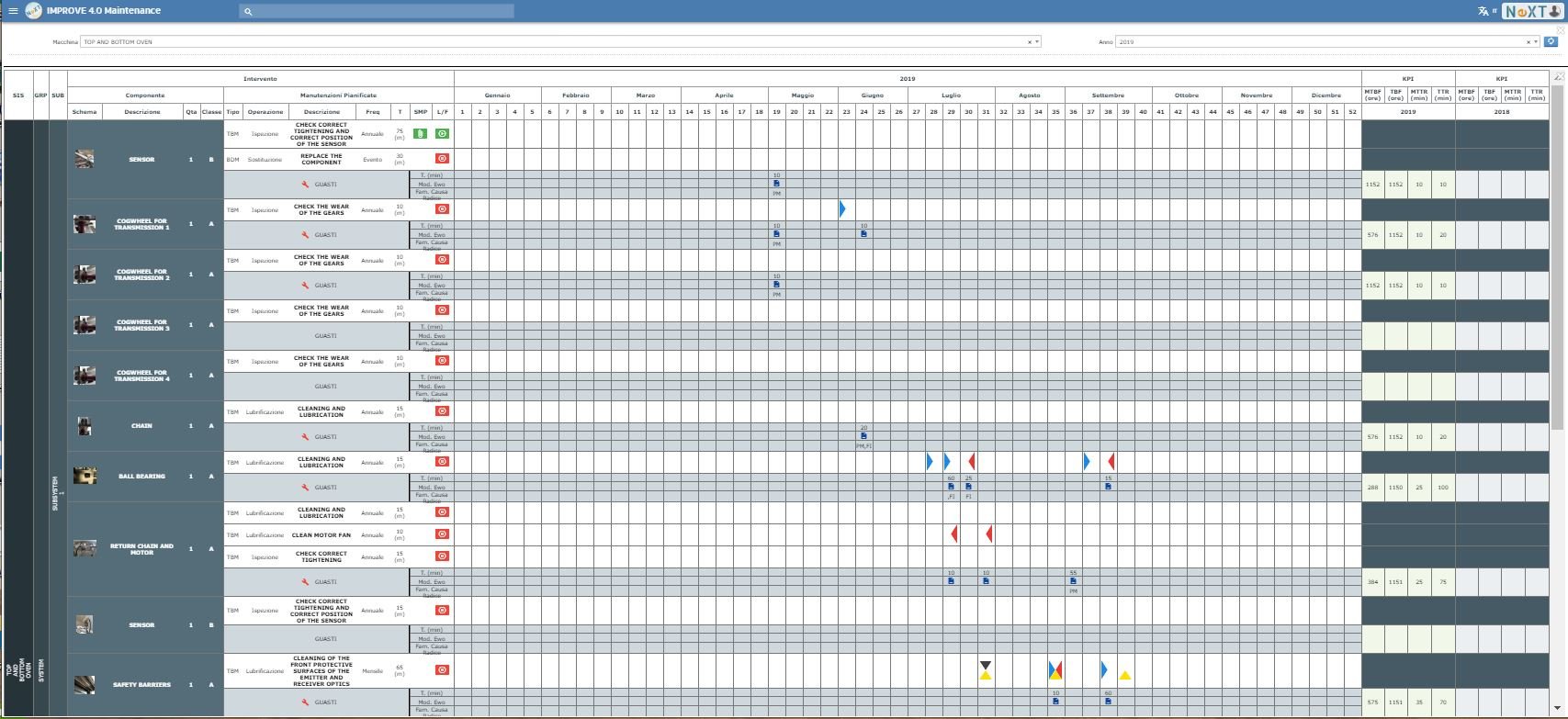

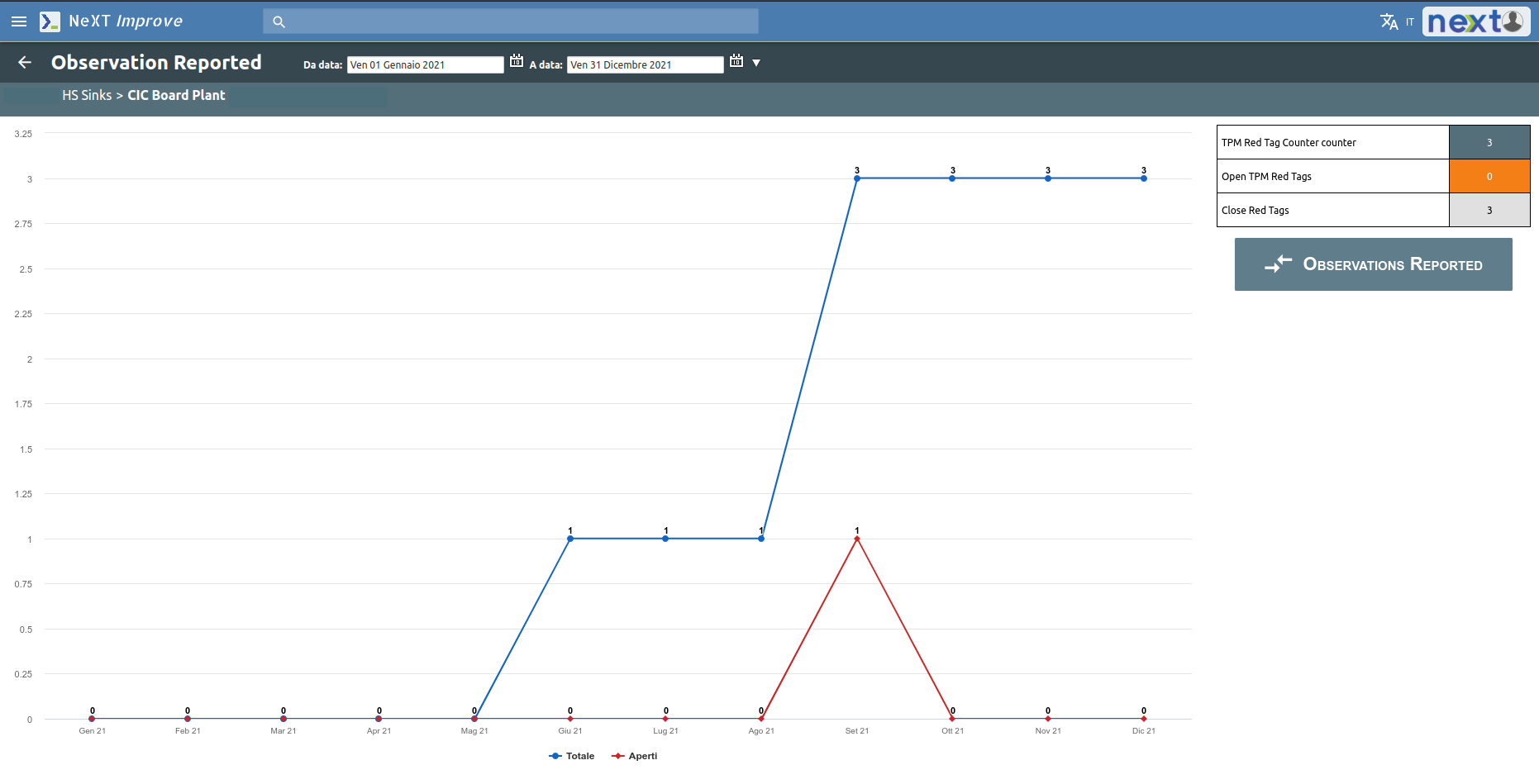

IMPROVE 4.0

NeXT has developed a software solution, IMPROVE 4.0, dedicated to the continuous improvement of industrial production processes.With IMPROVE 4.0, the management team can monitor the performance of each machine, department or plant, discovering where efficiency losses occur.Knowledge of data, nowadays, is the basis of competitiveness. In addition, several IMPROVE 4.0 solutions originate in World Class Manufacturing contexts. It is installed in 30 countries, in more than 100 industrial plants with a total of more than 5,000 production lines.

PROLED

Software made for Enel for the design of power distribution lines. To date, more than 10,000 km of power lines have been designed with ProLED. It is used by more than 2,000 Enel designers and hundreds of external designers.Currently, ProLED is the standard in Italy for the design of new power lines or the verification of existing lines redesigned for the installation of optical fiber.