The ID Factory

End to end supply chain traceability solution for the fashion industry

Start-up of Regione Marche

Description

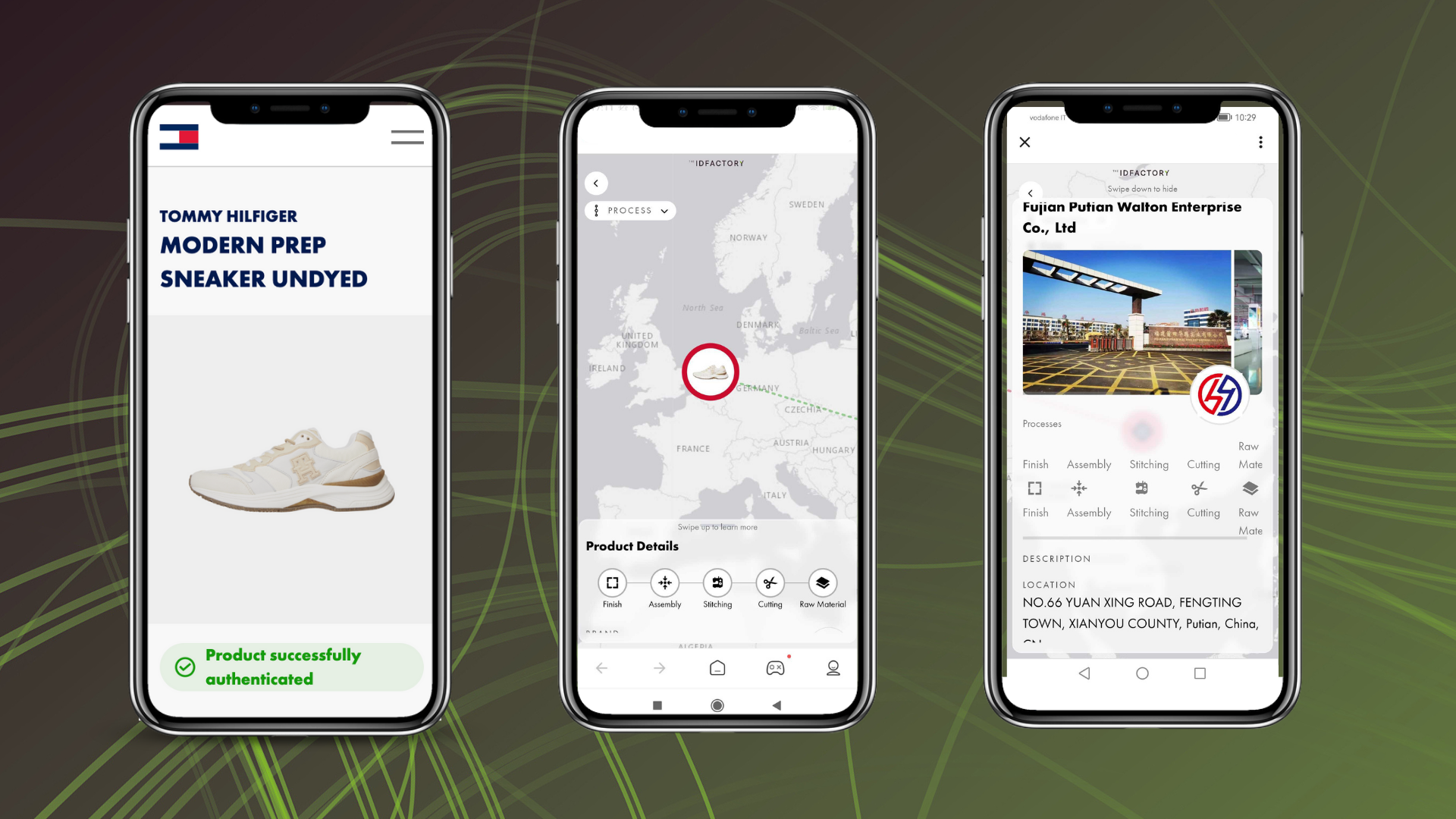

The ID Factory is a supply chain traceability platform (SaaS) that, through the creation of a digital ID, allows fashion companies to gain end-to-end transparency over their global supply chain.

We digitize operations like quality control, compliance, extended procurement and traceability through a dynamic database integrated with any management system.

A digital product passport enabled by a physical and digital traceability at scale.

Brands such as Geox, Hugo Boss, Tommy Hilfiger, Tamaris, s.Oliver and more than 600 supply chain stakeholders in 22 countries worldwide embraced full transparency thanks to The ID Factory’ solution.

The ID Factory is a Benefit Company and B Corp certified.