2SMArtEST

2SMArtEST - Shape Memory Alloy-based SMArt Engineering Solutions and Technologies

Start-up of Regione Calabria

Description

Our History

2SMArtEST is an innovative startup and spinoff company of University of Calabria – UniCal (Rende, IT) supported by the European Center for Nuclear Research – CERN (Geneva, CH). The company was established in 2019 based on a business idea coming from an R&D collaborative project between UniCal and CERN (https://home.cern/news/news/engineering/shape-memory-material-provides-solution-hl-lhc).

Our Business

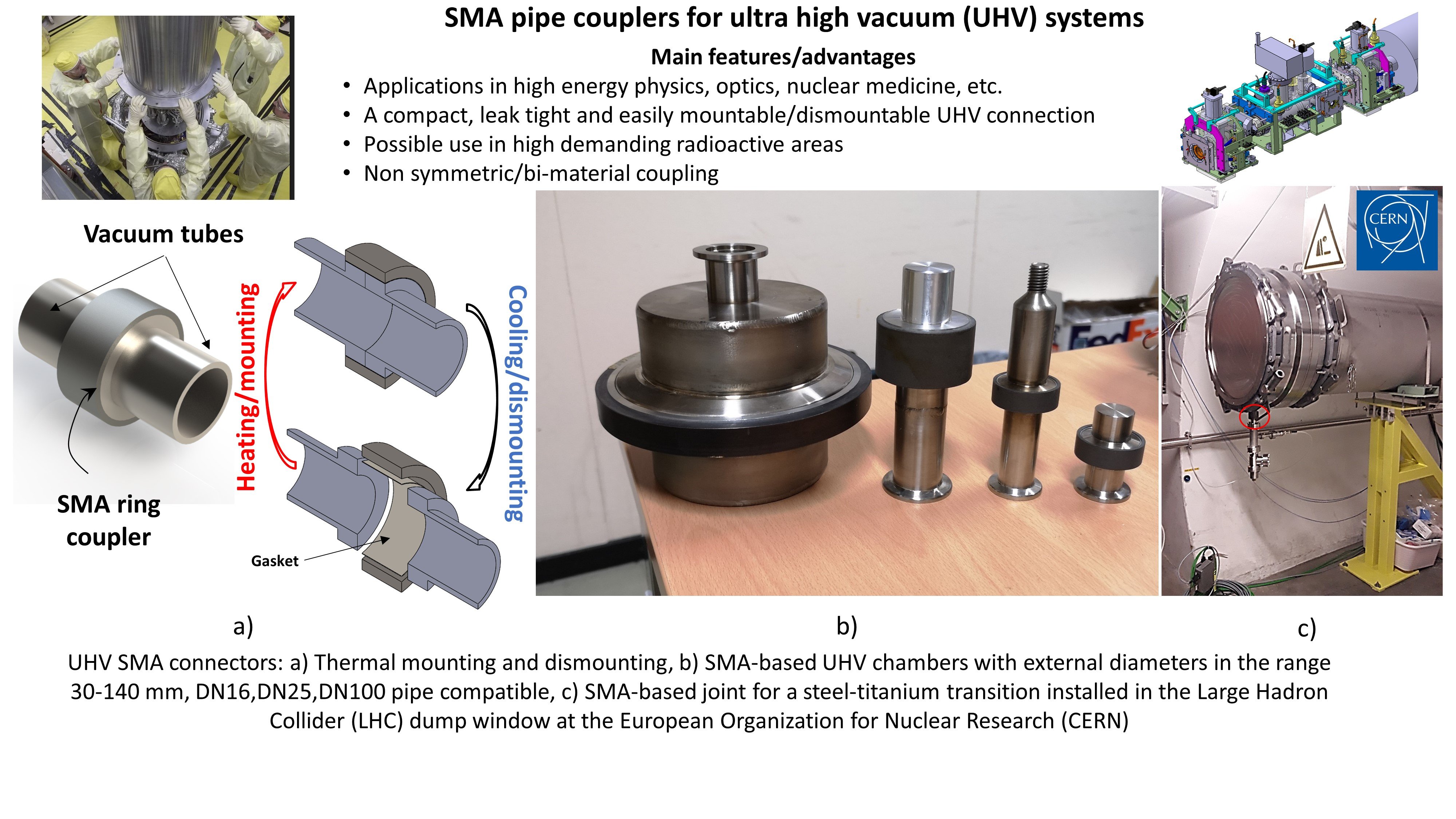

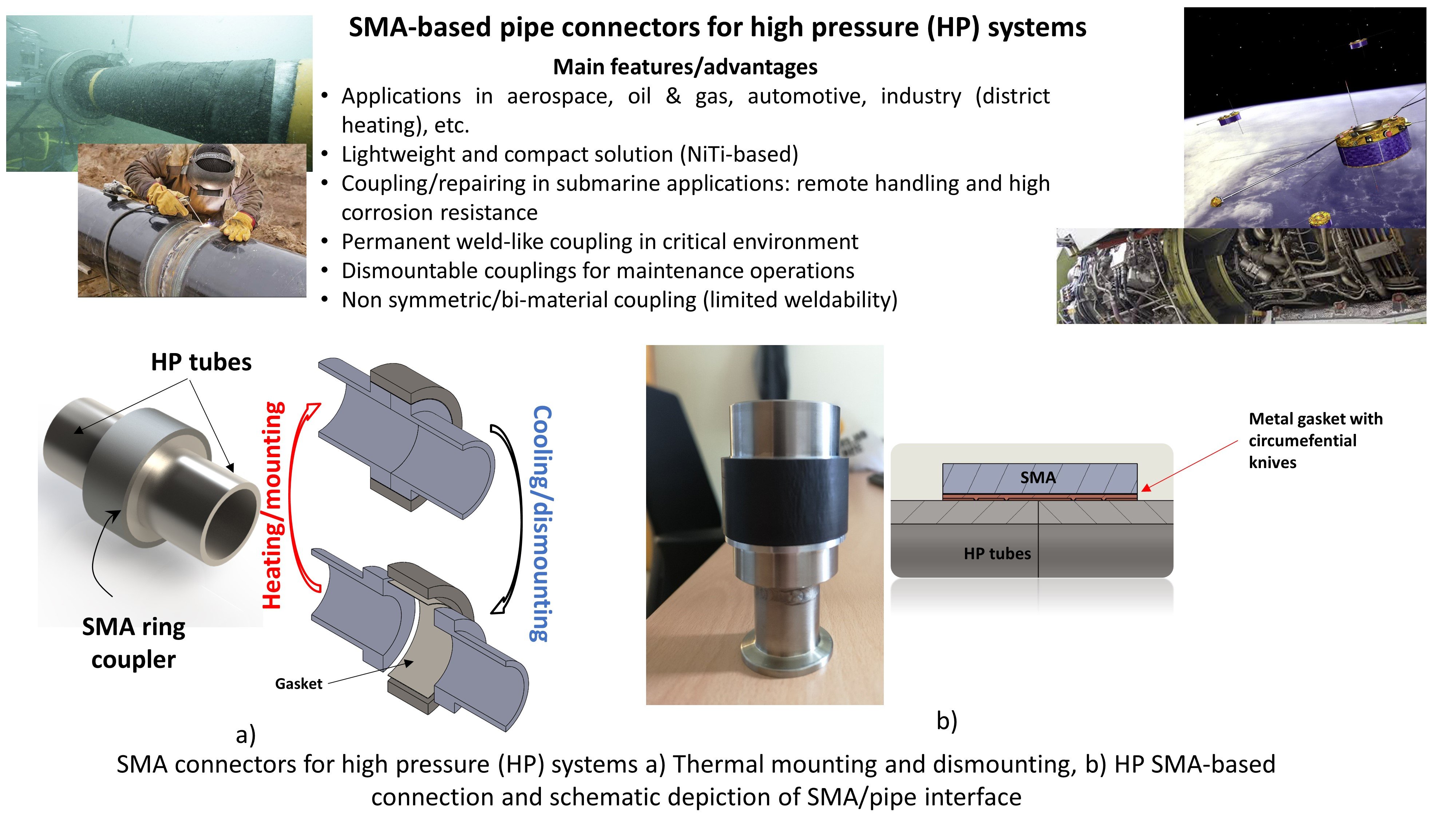

Our core business consists in the development and industrialization of novel/SMART leak tight pipe-coupling systems, based on shape memory alloys (SMAs). These systems are extremely compact and lightweigth and can be used in critical/harsh environment with limited human access thanks to the possibility of remote mounting and dismounting operations. Besides this main business, 2SMArtEST can offer B2B support to several industrial sectors, within the context of Smart Manufacturing and Industry 4.0, through design, manufacturing, testing and validation of custom based SMART solutions, exploiting the unique features of SMAs.

Website: https://2smartest.com